Integrated systems: innovative bottle lines for solid dose products

Uhlmann presents two pharmaceutically compliant, integrated lines for the packaging of tablets in bottles in the form of the IBC 150 and IBC 240. Capsules and coated tablets can also be filled into bottles on these Uhlmann lines and efficient labeling follows using the integrated Labeler L 180. Uhlmann offers efficiency, flexibility, and a high level of operating comfort with an integrated solution for the packaging of solids in bottles.

Find the suitable bottle lines

Innovative bottle line for the packaging of tablets and capsules in bottles

Uhlmann presents two pharmaceutically compliant packaging lines for tablets and capsules in bottles in the form of the IBC 150 and IBC 240 – a new machine generation for very efficient, flexible packaging combined with easy handling.

Performance at its best

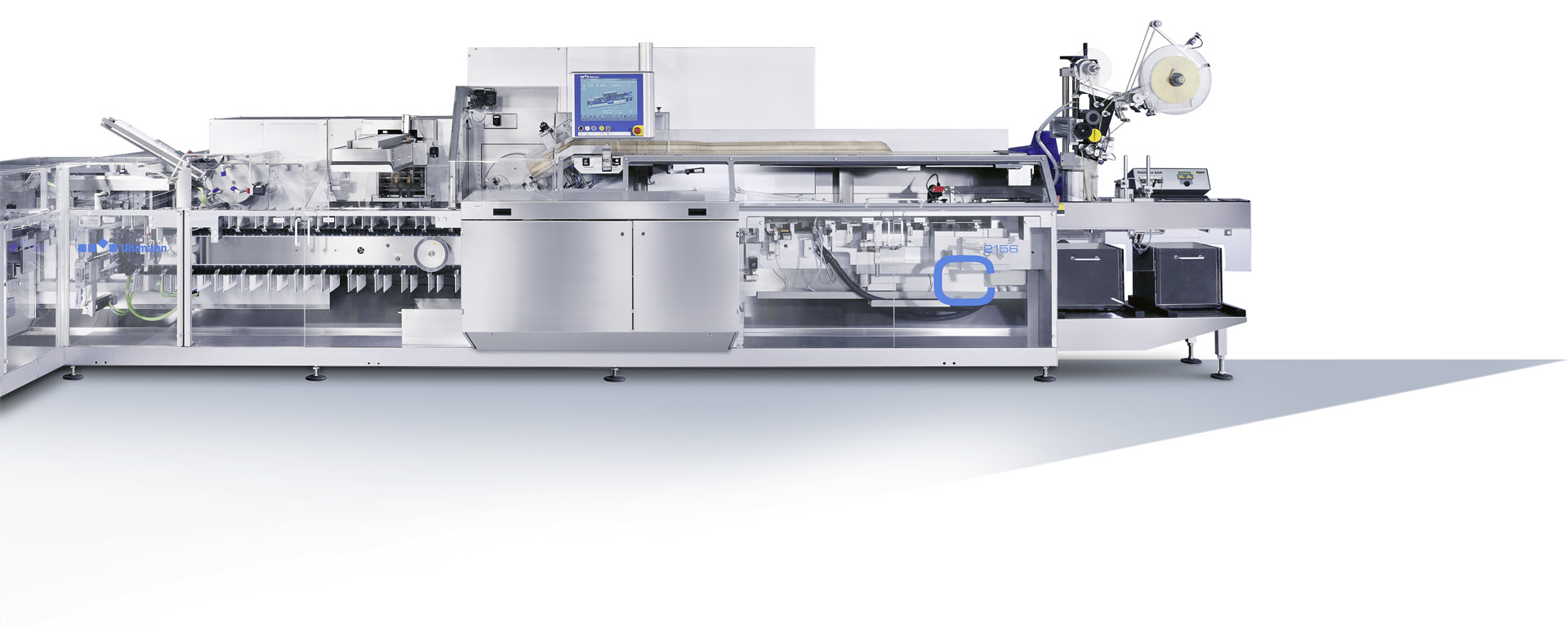

Pharmaceutically compliant counting, packaging, and labeling: the IBC 240 is an end-to-end system for the non-stop packaging of tablets and capsules in bottles. Developed taking pharmaceutical requirements into account, the IBC 240 stands for maximum efficiency.

Flexible and efficient labeling

The Labeler L 180 is a GMP-compliant, flexible, continuous motion system. Handling up to 180 bottles per minute, it ideally complements the IBC 150. The L 180 has a large format area for the efficient labeling of round, rectangular, and oval containers made of plastic or glass.

Bottle-filling lines from Cremer Speciaalmachines B.V.

As a technology specialist for counting systems, Cremer has been a member of the Uhlmann Group since 2017. The company, based in Lisse (Netherlands), develops and markets bottle-filling systems – starting with compact tablet and capsule counters, and ranging to high-end modular counting and in-motion bottle filling systems. Cremer pays particular attention to innovative technology combined with top performance, efficiency, and long service life.

A comparison of our bottle lines & labeler

| Max. output | Max. counting speed | Bottle volume | Processable bottle shapes | ||

|---|---|---|---|---|---|

| 150 bottles/min. | 24,000 products/min. | 30 - 1,500 cc | round, rectangular, oval | ||

| 240 bottles/min. | 42,000 products/min. | 30 - 950 cc | round, rectangular, oval | ||

| 180 bottles/min. (round), 165 bottles/min. (rectangular, oval) | - | - | round, rectangular, oval | ||

Newsroom

All

Products

Customer Stories

Blister machine

BLU 200

Blister Lines

BEC 200

Cartoners

Feeders

Parenterals

12.04.2024

Blow-Fill-Seal ampoules: labeled precisely, packaged efficiently

When requirements are so unusual that no standard machine can meet them, it’s time for Uhlmann to take the stage. Under the…

Products

News

Parenterals

PTC 200

12.03.2024

Digital PTC 200 Show: Experience our machine highlight on Uhlmann Plaza

Flexible, sustainable, future-proof: The Parenteral Tray Center PTC 200 is made for all requirements in Parenteral Packaging…

Products

Customer Stories

Blister machine

BLU 200

Blister Lines

BEC 200

Cartoners

Feeders

Parenterals

30.11.2023

Rust never has a chance!

Active ingredients react with the oxygen and humidity of their environment – some more, some less. CordenPharma deals with a…

Company

News

Sustainability

27.11.2023

EcoVadis Rating: Uhlmann awarded a gold medal yet again

With an improvement from 69 to 71 points, Uhlmann Pac-Systeme GmbH & Co KG has once again secured the gold medal in the EcoVadis…

Company

Trade press

Sustainability

23.11.2023

Uhlmann Pac-Systeme expands sustainable infrastructure at its Laupheim site

With the opening of the new parking garage at the company's headquarters, employees now have a total of 743 parking spaces at…

Company

Parenterals

Products

News

20.11.2023

The future of parenteral packaging live at Uhlmann in Laupheim

The topic of sustainability is also becoming increasingly important in the pharmaceutical industry, and the challenges that this…

Products & Format Parts

Products

Customer Stories

Blister machine

BLU 200

Blister Lines

BEC 200

Cartoners

Feeders

Parenterals

12.04.2024

Blow-Fill-Seal ampoules: labeled precisely, packaged efficiently

When requirements are so unusual that no standard machine can meet them, it’s time for Uhlmann to take the stage. Under the…

Products

News

Parenterals

PTC 200

12.03.2024

Digital PTC 200 Show: Experience our machine highlight on Uhlmann Plaza

Flexible, sustainable, future-proof: The Parenteral Tray Center PTC 200 is made for all requirements in Parenteral Packaging…

Products

Customer Stories

Blister machine

BLU 200

Blister Lines

BEC 200

Cartoners

Feeders

Parenterals

30.11.2023

Rust never has a chance!

Active ingredients react with the oxygen and humidity of their environment – some more, some less. CordenPharma deals with a…

Company

Parenterals

Products

News

20.11.2023

The future of parenteral packaging live at Uhlmann in Laupheim

The topic of sustainability is also becoming increasingly important in the pharmaceutical industry, and the challenges that this…

Products

Customer Stories

Blister machine

BLU 200

Blister Lines

BEC 200

Cartoners

Feeders

Parenterals

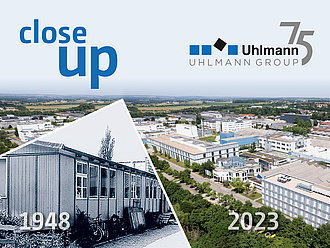

19.10.2023

75 years Uhlmann Pac-Systeme

In 1948, Germany was divided into four occupation zones and Berlin was supplied via an airlift. Prince Charles and Alice Cooper…

Products

News

Digital

Track&Trace

03.08.2023

The people behind Uhlmann Track & Trace: Christian Schädler – Team leader, implementer, mover & shaker

With Track & Trace by Uhlmann, our customers get a perfect combination of machine, components, software and service. But how does…

Services

Services

Trade press

04.05.2023

Uhlmann Pac-Systeme presents innovative service solutions for more sustainability in the packaging process

An important element in making packaging machines more efficient and thus more environmentally friendly is their adaptation to…

Services

News

Training services

15.03.2022

Any time and any place: Individual training courses from Uhlmann

Have the coronavirus restrictions thwarted your efforts to offer advanced training in the past two years? Does your employees'…

Services

News

Support services

01.02.2022

Even more manpower in the Uhlmann spare parts service

Uhlmann is taking its comprehensive spare parts service one step further: With even more manpower and concentrated expertise, the…

Services

News

Training services

Blister Lines

BEC 300

21.01.2022

BEC training for smooth commissioning

How does Uhlmann support pharmaceutical companies in the smooth commissioning of new packaging lines? With extensive training for…

Services

News

Support services

10.11.2021

Ramp-Up3 Support

Get through the initial phase with confidence with Ramp-Up3 Support

How can you speed up the production ramp-up of new or…

Services

Customer Stories

Support services

E-Commerce

04.10.2021

BAYER uses Uhlmann E-Commerce to implement digital purchasing processes

The B2B integration with Uhlmann is an important milestone and will enable new, timely processes in terms of the procurement of…

Digital

Products

News

Digital

Track&Trace

03.08.2023

The people behind Uhlmann Track & Trace: Christian Schädler – Team leader, implementer, mover & shaker

With Track & Trace by Uhlmann, our customers get a perfect combination of machine, components, software and service. But how does…

Products

News

Digital

Track&Trace

28.07.2023

The people behind Uhlmann Track & Trace: Dalila Kajevic – Track & Trace Expert, Tester, Customer Understander

Uhlmann Track & Trace offers pharmaceutical manufacturers a high level of security. But how is the software developed and tested…

Products

News

Digital

Track&Trace

24.07.2023

The people behind Uhlmann Track & Trace: Georg Schick – Networker, Showman and Helper with Heart

Uhlmann has been offering Track & Trace since 2008. Many customers view this as an advantage because it allows them to obtain…

Products

News

Digital

Track&Trace

21.07.2023

The people behind Uhlmann Track & Trace: Frank Bixenmann – Solution wizard, team player and connectivity expert

With its "Track & Trace" solutions, Uhlmann offers the perfect combination of machinery, components, software and service. But who…

Company

Trade press

Digital

Track&Trace

01.06.2023

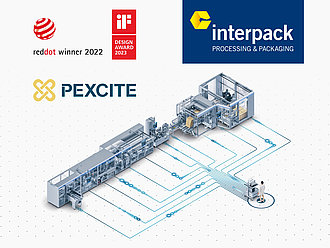

Pexcite receives an iF Design Award

For the second time, the Pexcite team from Uhlmann Pac-Systeme has reason to celebrate a design award: The Pexcite software,…

Digital

Trade press

04.05.2023

Design and control future-proof processes with Pexcite software solutions

Pharmaceutical and biotech companies face many complex new regulatory requirements. Especially sustainability which has become…

Company

Company

News

Sustainability

27.11.2023

EcoVadis Rating: Uhlmann awarded a gold medal yet again

With an improvement from 69 to 71 points, Uhlmann Pac-Systeme GmbH & Co KG has once again secured the gold medal in the EcoVadis…

Company

Trade press

Sustainability

23.11.2023

Uhlmann Pac-Systeme expands sustainable infrastructure at its Laupheim site

With the opening of the new parking garage at the company's headquarters, employees now have a total of 743 parking spaces at…

Company

Parenterals

Products

News

20.11.2023

The future of parenteral packaging live at Uhlmann in Laupheim

The topic of sustainability is also becoming increasingly important in the pharmaceutical industry, and the challenges that this…

Company

Trade press

Digital

Track&Trace

01.06.2023

Pexcite receives an iF Design Award

For the second time, the Pexcite team from Uhlmann Pac-Systeme has reason to celebrate a design award: The Pexcite software,…

Company

Trade press

04.05.2023

Efficient Packaging Competence Consulting for sustainable packaging from Uhlmann Pac-Systeme

Bundled competence at interpack 2023: With its Packaging Competence Consulting, Uhlmann Pac-Systeme presents a holistic approach…

Company

Trade press

16.03.2023

Sustainability: From nice-to-haves to must-haves – with innovative solutions from Uhlmann Pac-Systeme

Sustainable Pharma – this can only be achieved by companies that keep an eye on the entire development and production process up…

Customer Stories

Products

Customer Stories

Blister machine

BLU 200

Blister Lines

BEC 200

Cartoners

Feeders

Parenterals

12.04.2024

Blow-Fill-Seal ampoules: labeled precisely, packaged efficiently

When requirements are so unusual that no standard machine can meet them, it’s time for Uhlmann to take the stage. Under the…

Products

Customer Stories

Blister machine

BLU 200

Blister Lines

BEC 200

Cartoners

Feeders

Parenterals

30.11.2023

Rust never has a chance!

Active ingredients react with the oxygen and humidity of their environment – some more, some less. CordenPharma deals with a…

Products

Customer Stories

Blister machine

BLU 200

Blister Lines

BEC 200

Cartoners

Feeders

Parenterals

19.10.2023

75 years Uhlmann Pac-Systeme

In 1948, Germany was divided into four occupation zones and Berlin was supplied via an airlift. Prince Charles and Alice Cooper…

Products

Customer Stories

Blister machine

BLU 200

Blister Lines

BEC 200

Cartoners

Feeders

Parenterals

25.04.2023

Always one step ahead!

For many years, multi-material packaging was hard to beat when it came to most of the parameters important to pharmaceutical…

Products

Customer Stories

Blister Lines

BEC 200

21.04.2023

Efficient sustainability: BEC 400 for PP mono blisters and more

With our sustainability strategy in mind, we opted for the BEC 400 blister line, which can also produce PP mono blisters. It was…

Products

Customer Stories

Blister Lines

BEC 200

18.04.2023

In operation at Develco: Multifunction line for blisters and bottles

High quality, safety and efficiency are our top priorities. With Uhlmann, we have configured a pharmaceutical packaging line in…