Find the right blister line

Our blister lines at a glance

| PERFORMANCE | MINIMUM LENGTH BASE MODEL | CHARGE SIZE | MAX. FORMAT AREA BLISTER MODULE [Feed x Width] | ||

|---|---|---|---|---|---|

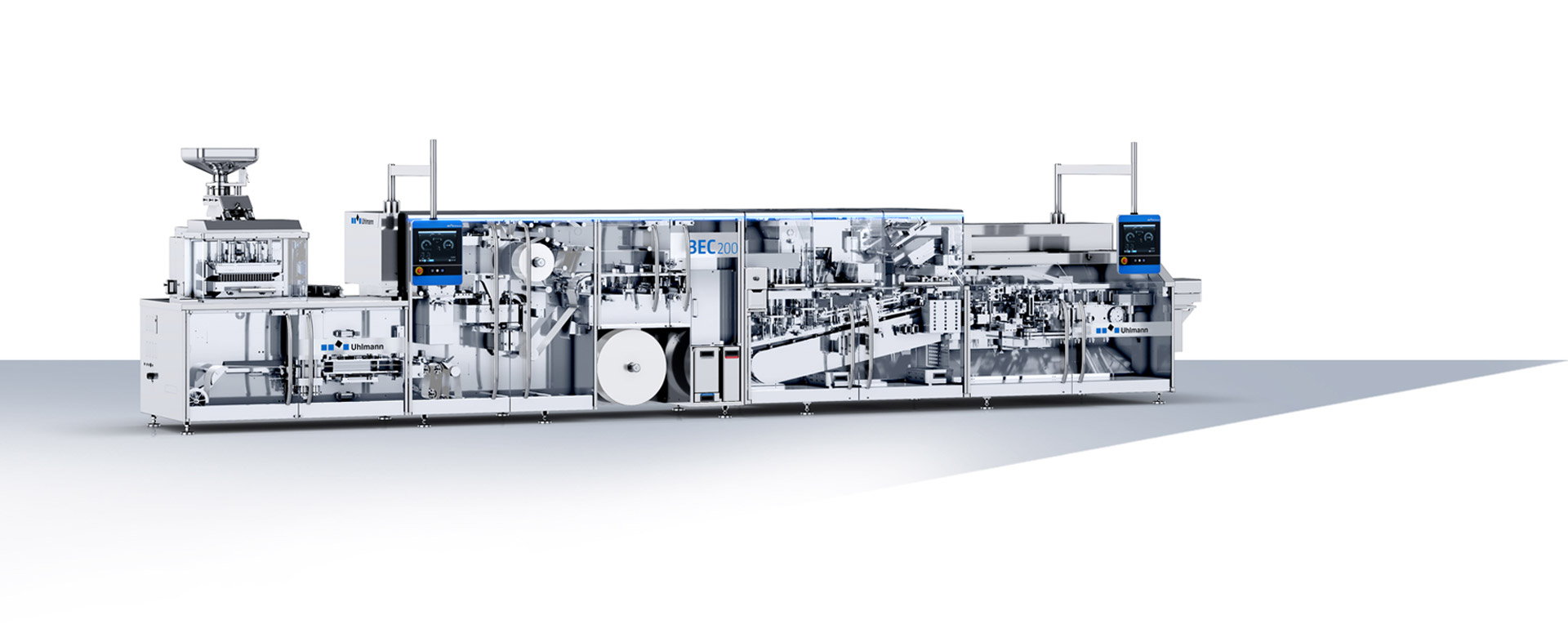

| Max. 200 or 300 blisters/min. Max. 150 / 300 folding boxes/min. | 8.7 m | 2,000-50,000 packages | 200 x 145 mm | ||

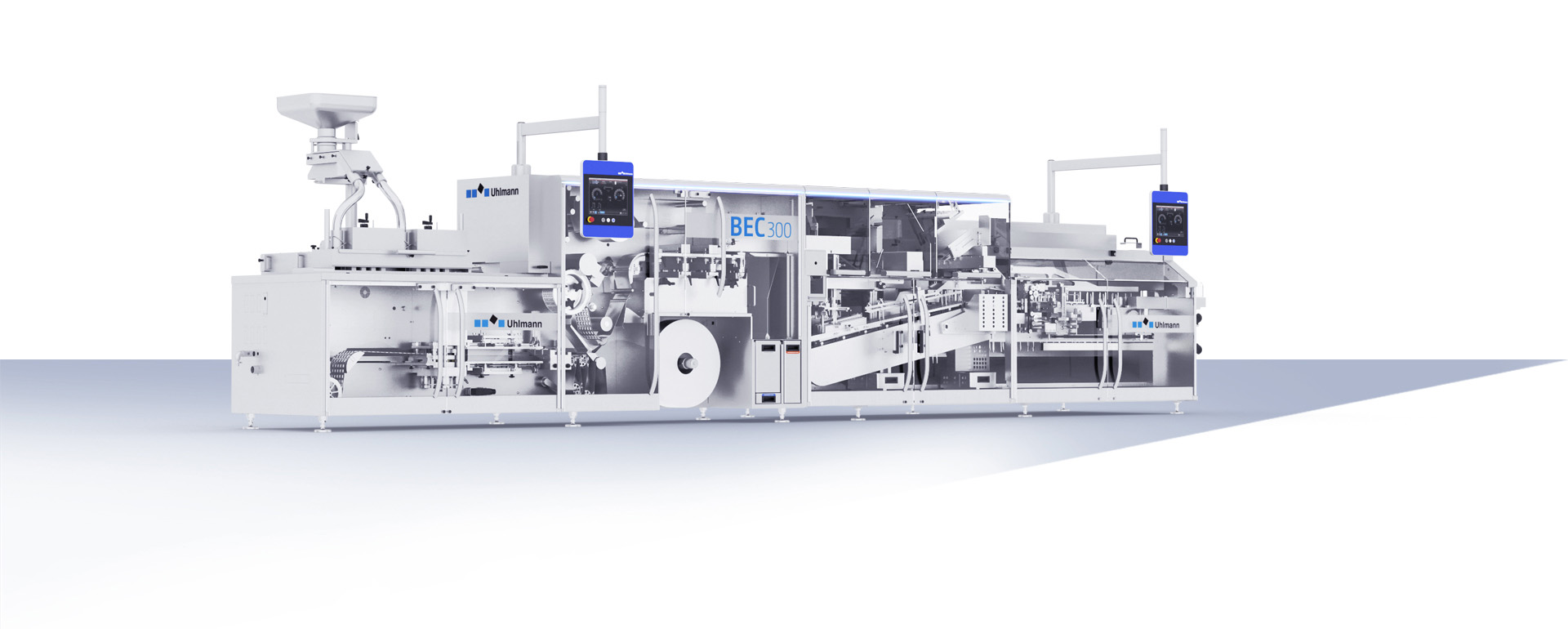

| Max. 150 / 300 blisters/min. Max. 150 / 300 folding boxes/min. | 7.9 m | < 70,000 packages | 200 x 145 mm | ||

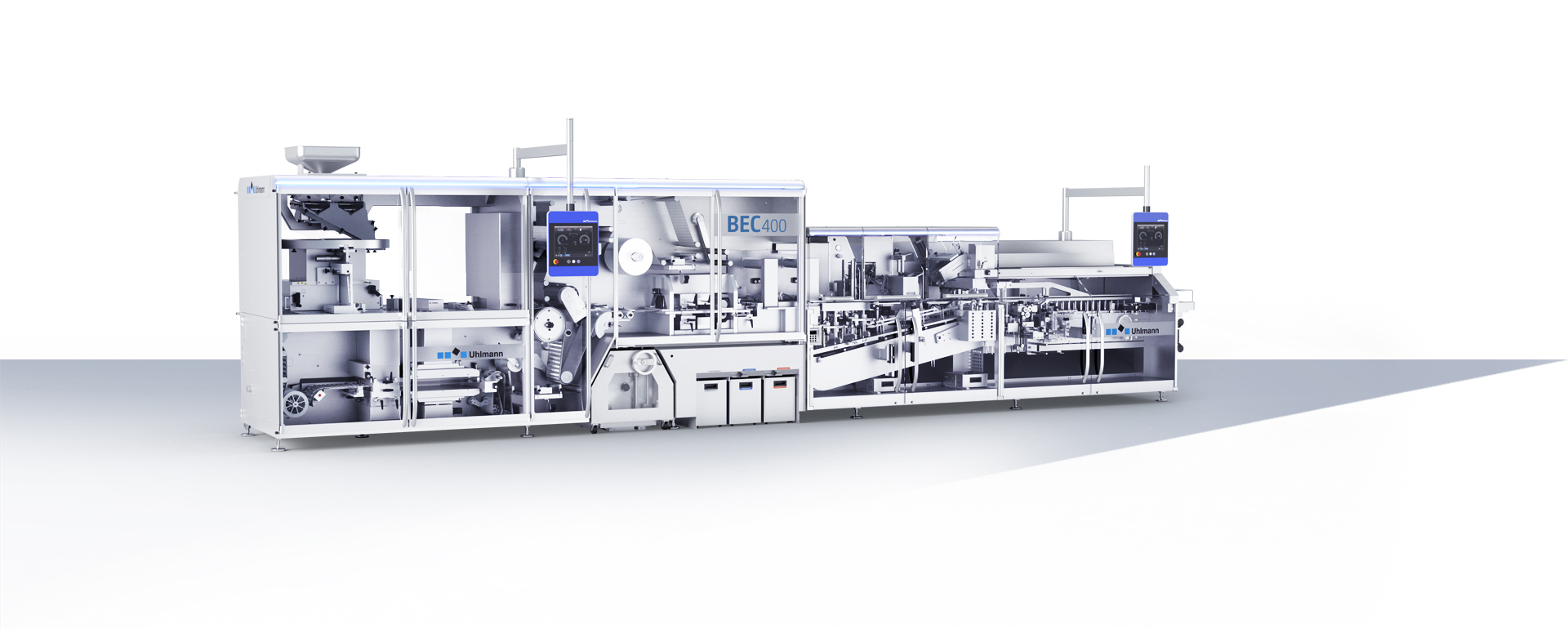

| Max. 400 blisters/min. Max. 150 folding boxes/min. | 8.4 m | 30,000-150,000 packages | 200 x 284 mm | ||

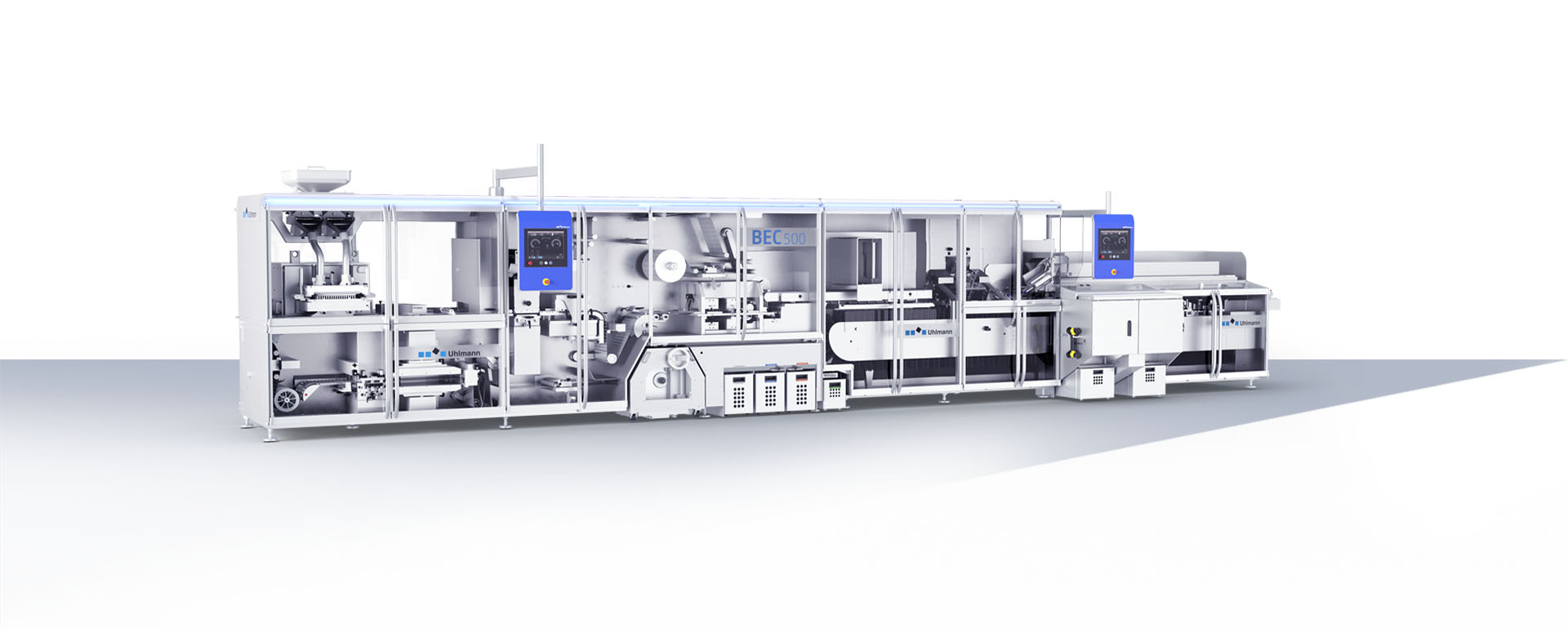

| Max. 500 blisters/min. Max. 300 / 500 folding boxes/min. | 9.8 m | > 150,000 packages | 200 x 284 mm | ||

| Max. 700 blisters/min. Max. 300 / 500 folding boxes/min. | 10.3 m | > 150,000 packages | 200 x 284 mm | ||

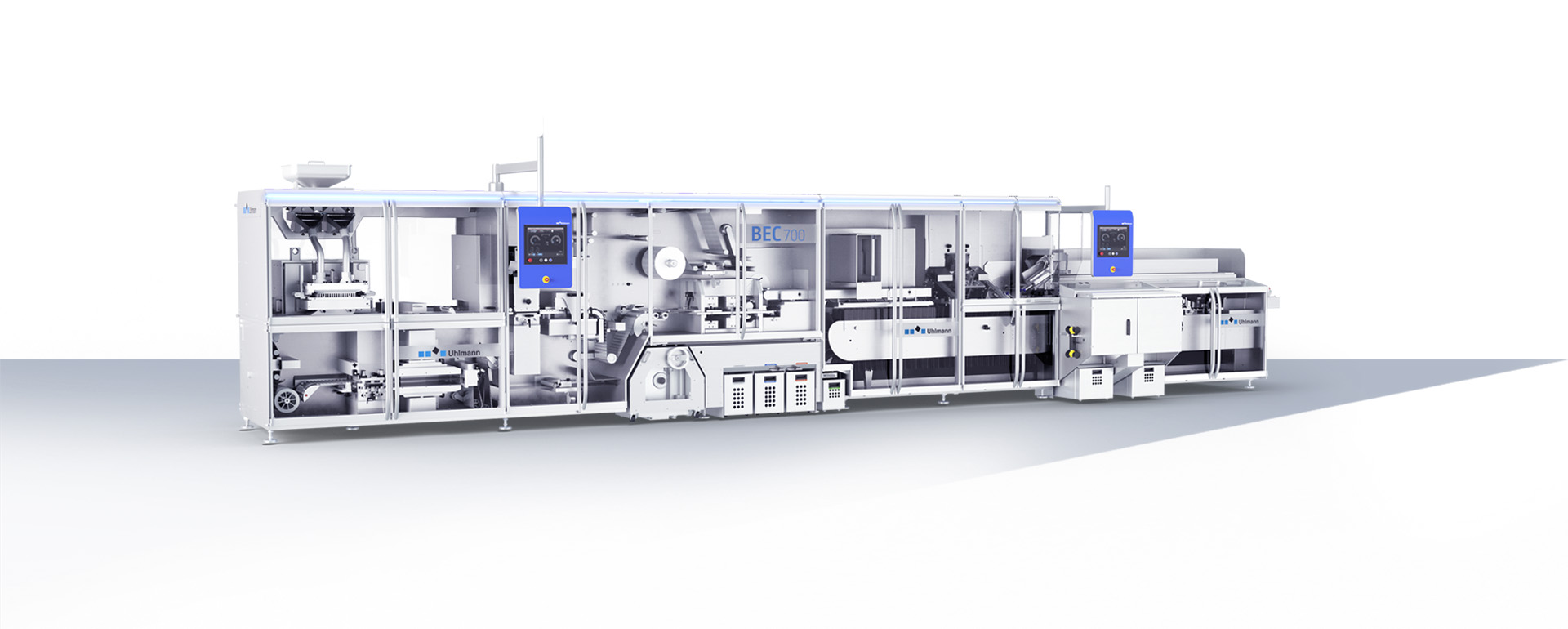

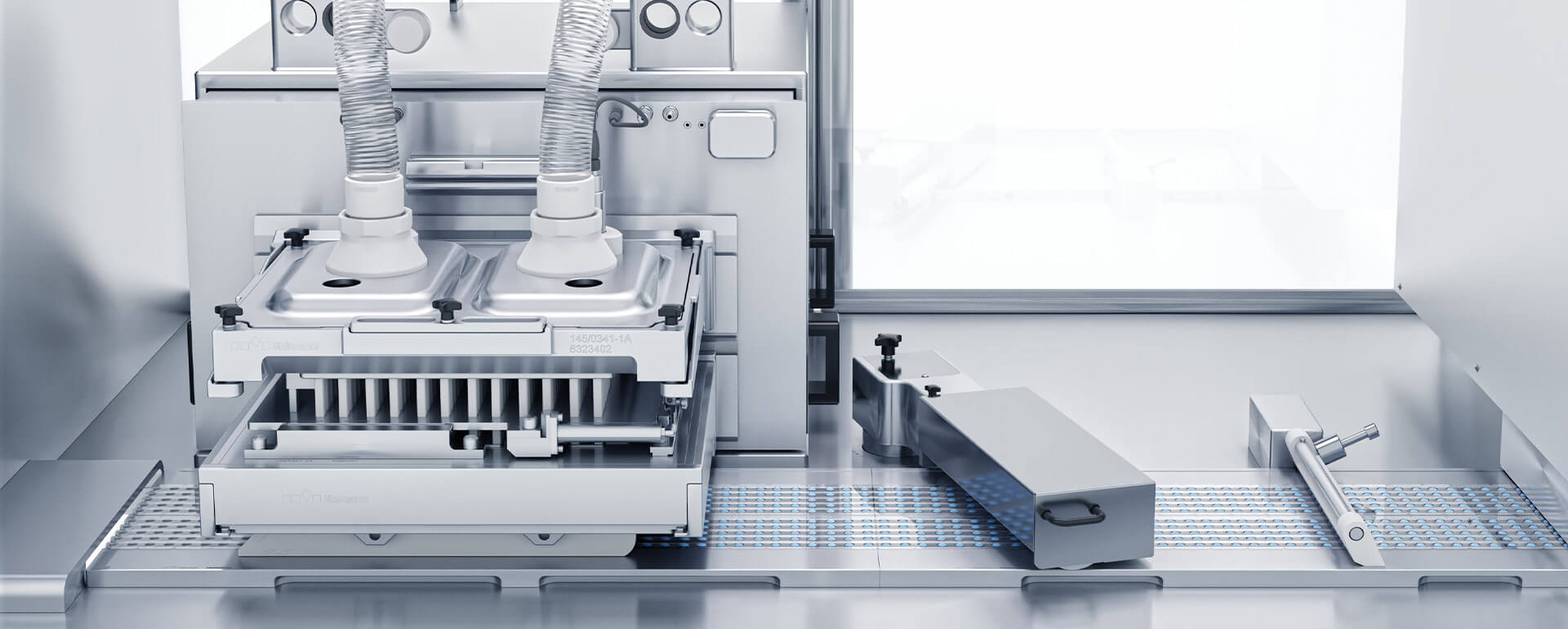

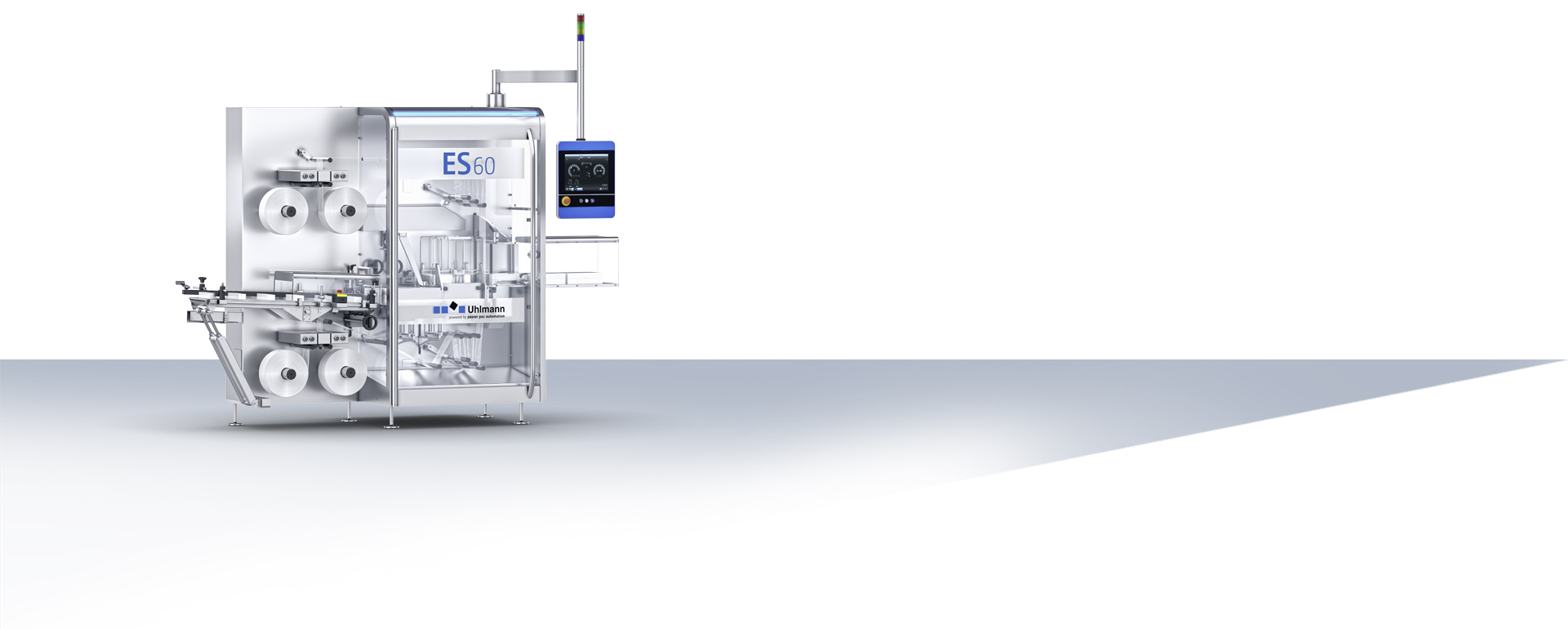

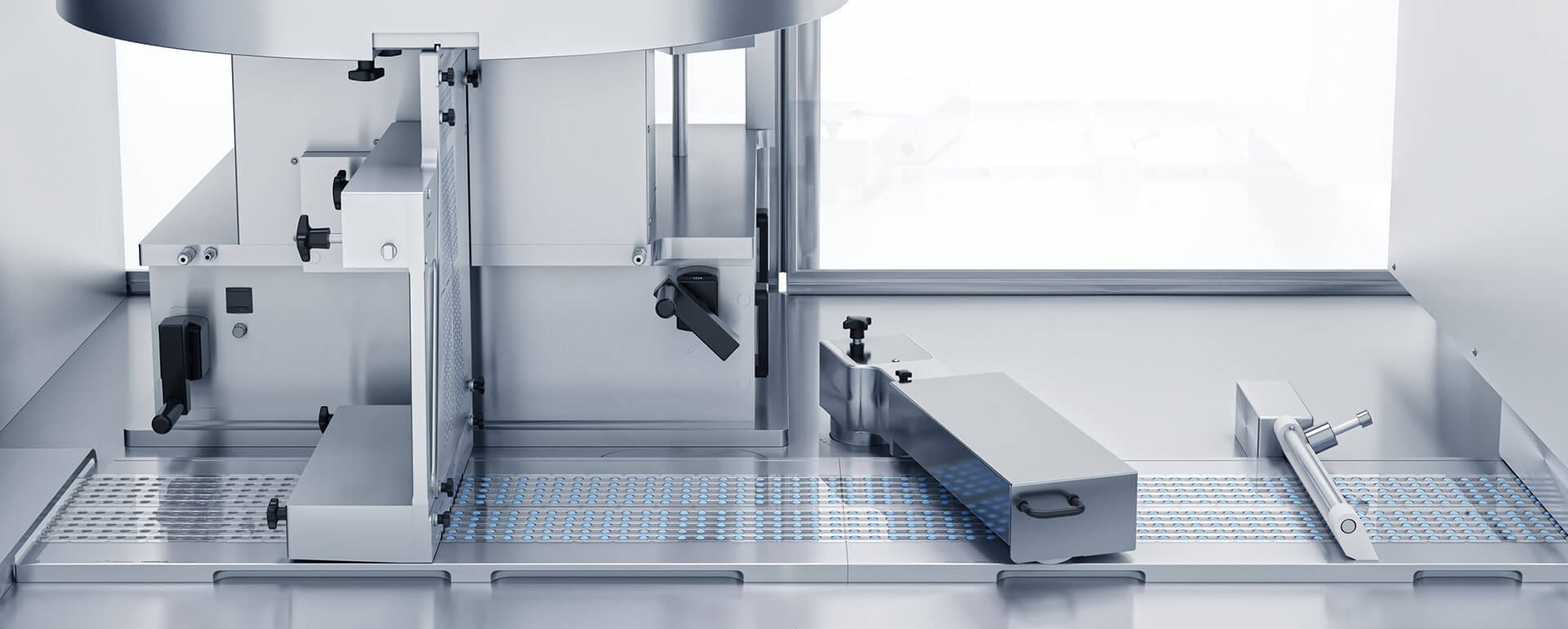

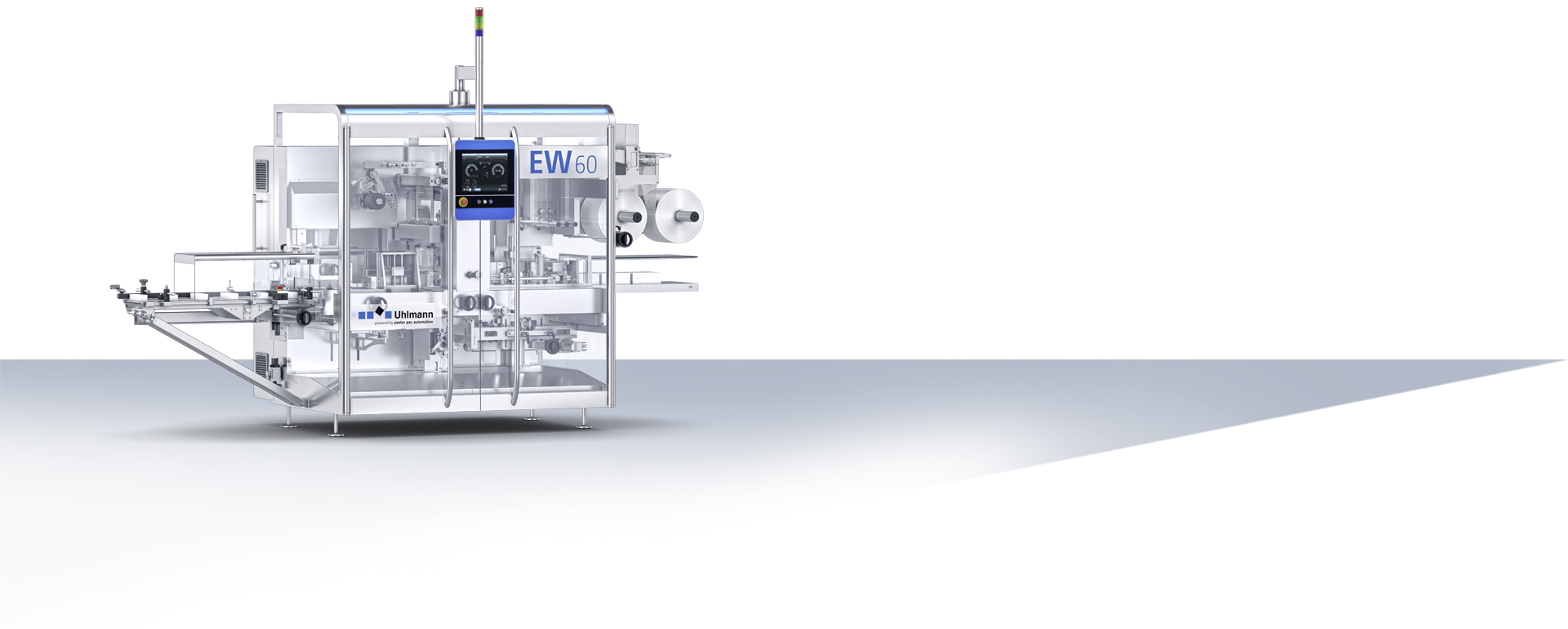

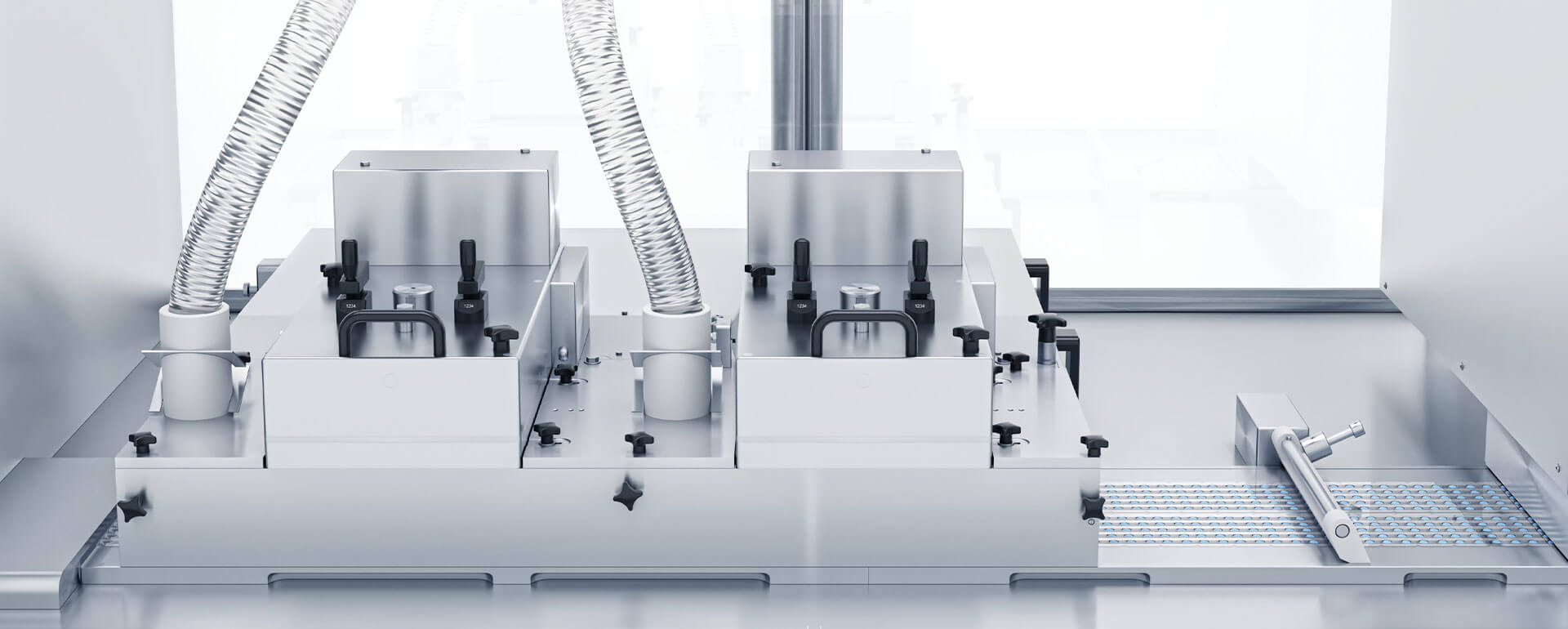

Powerful complete system for economical pharmaceutical packaging

With its Blister Express Centers (BEC), Uhlmann offers flexible pharmaceutical packaging at maximum output. The space-saving combination of blister machine and cartoner module is characterized by a high degree of flexibility, very fast format changes, and simple operation. In addition to efficient product changeovers, further advantages result from the modular design, the choice between plate and roller sealing, the high format variety, the digital servo technology, and the large format range.