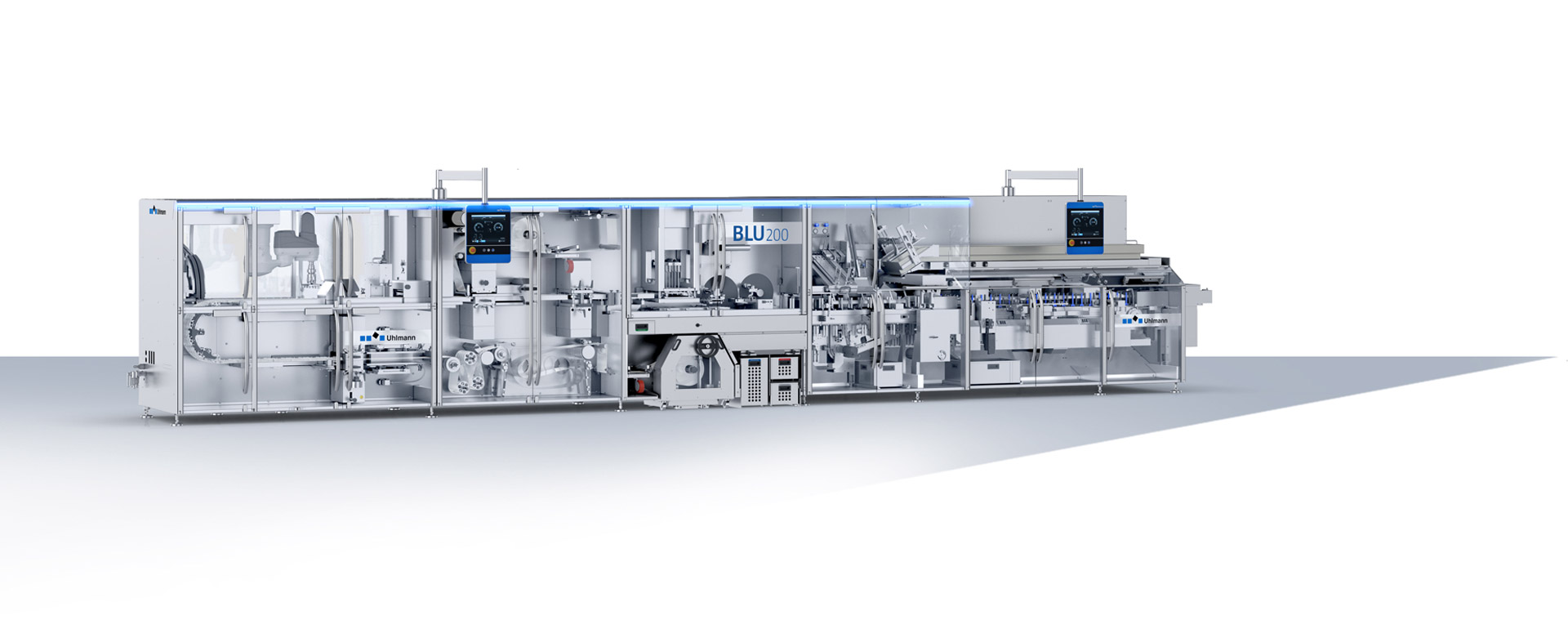

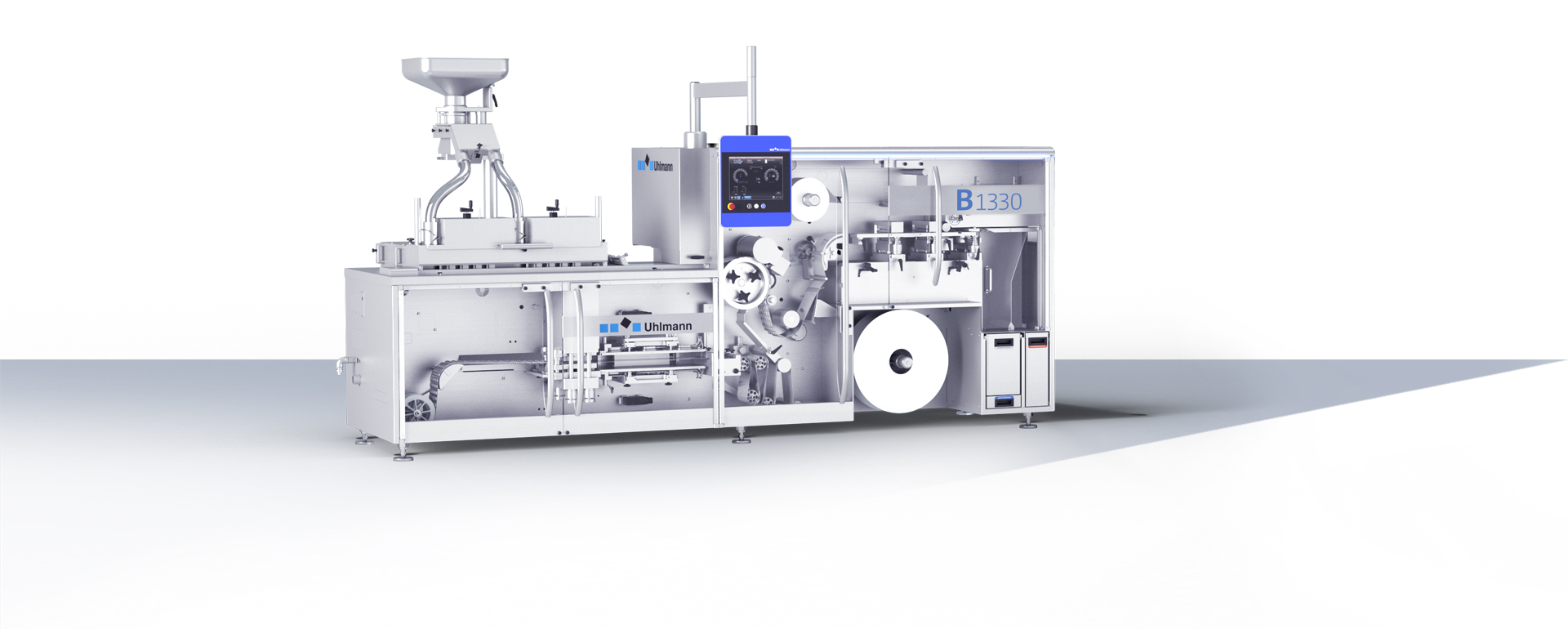

Gentle product handling and top performance

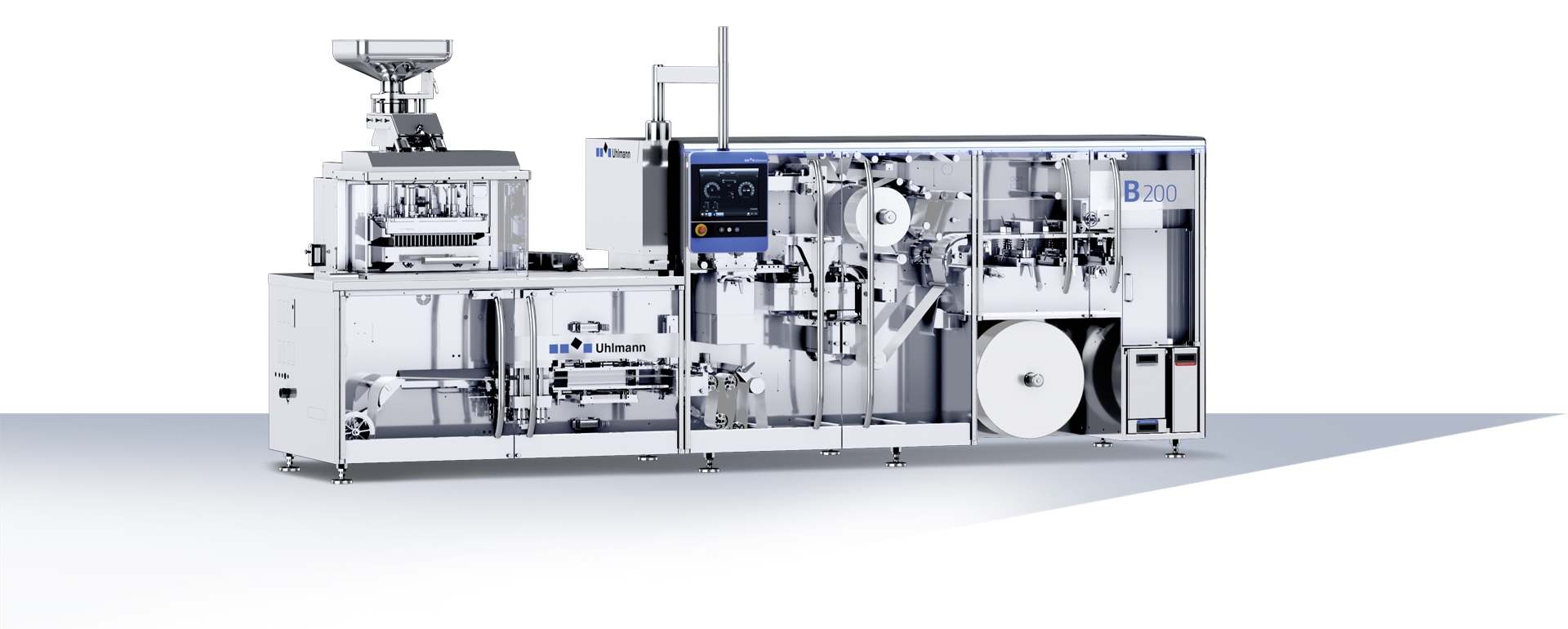

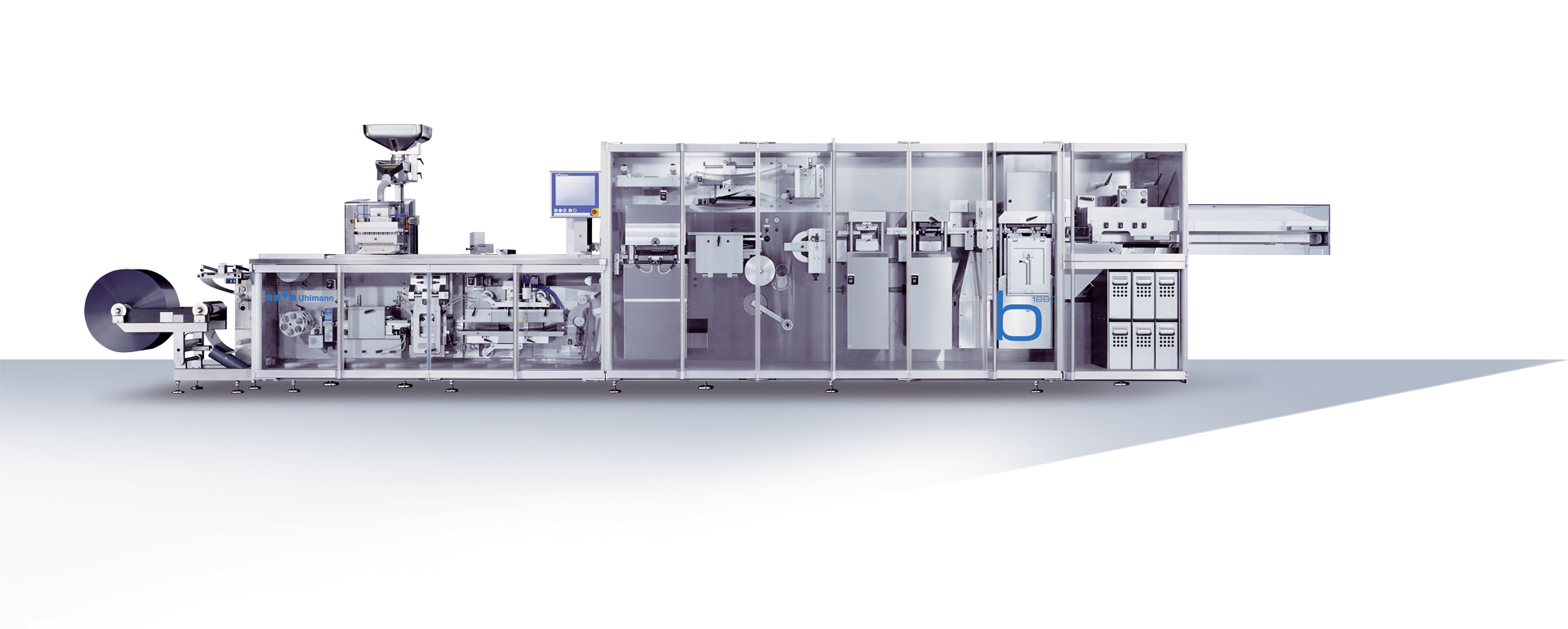

A packaging process that handles parenteral products with utmost care pays off because every instance of damage leads to extensive cleaning, extra work, and longer downtimes. Gentle handling during the entire packaging process of the BLU 200 protects the glass products against breakage. The low drop height during blister removal is one feature in this context.

The BLU 200 is complemented by the Cartoner C 200. This covers the complete format and output range of the blister machine and handles large blisters at an output of 120 cartons per minute, as well as small ones at a maximum speed of 200 cartons per minute.

Advantages of the BLU 200 at a glance

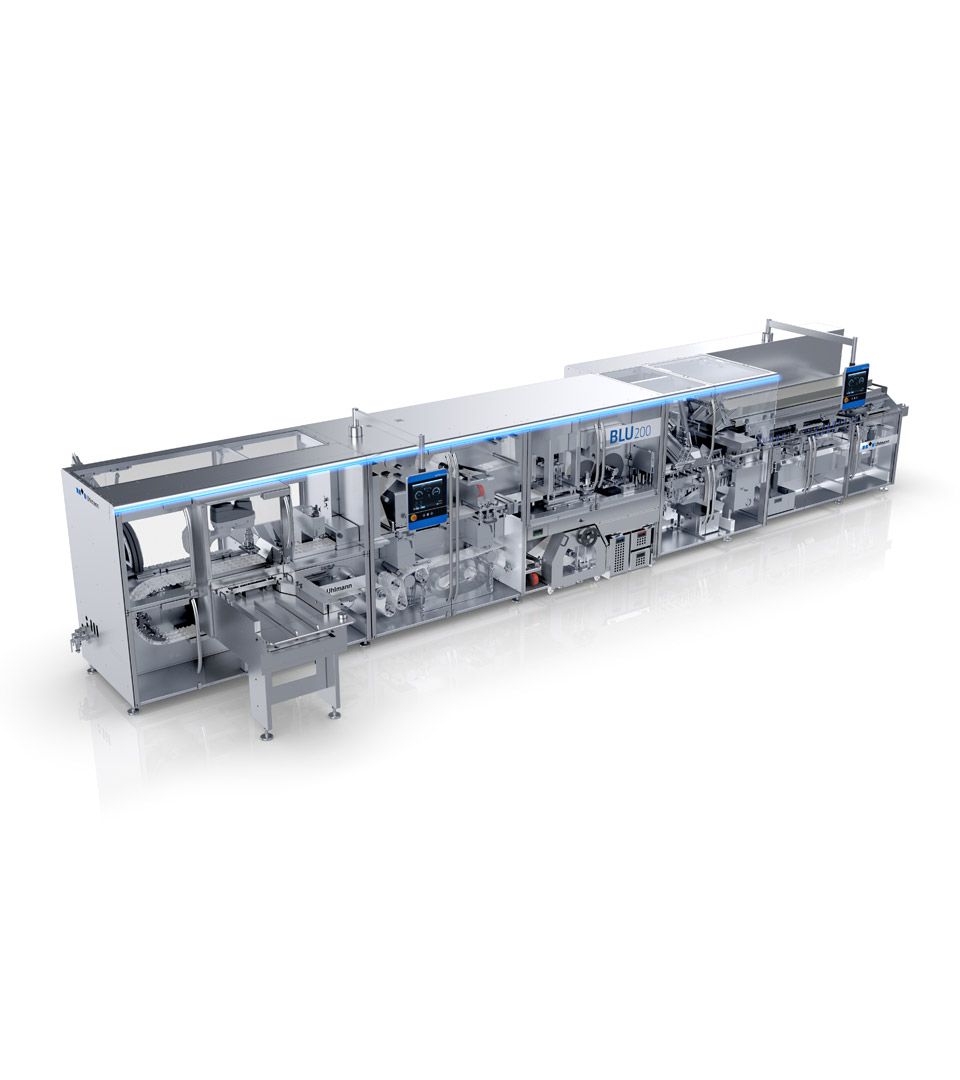

The modular design of the BLU 200 also enables the flexible packaging of smaller batches

Careful handling as well as the GMP-compliant machine design avoid damage to the parenteral products

Precision blister production and handling, state-of-the-art technology in the working stations, as well as the machine control system ensure top, reproducible results

Intuitive operation of the blister packaging machine and easy, guided format part changeovers using the SmartControl operating system; ideal access to the working stations

Formats make optimum use of the full web as products and blisters can be rotated; less waste and maximum machine output

BLU 200 in detail

| Sealing principle | platen sealing |

| Scope of application | parenteral products |

| Mode of operation | single- to five-lane / single- or double row |

| Max. output | 200 blisters/min. |

| Formats | ampoules, vials, cartridges, bottles (ø 8.25–30 mm), syringes (ø 6.5–26 mm) |

| Forming depth | 12–33 mm |

| Max. format area [index x width] | 173 x 206 mm |

The BLU 200 is a blister packaging line for the secondary packaging of syringes, ampoules, vials, cartridges, bottles, and pens. As parenteral products are increasingly being packaged in smaller batches, cost-efficient packaging is gaining in importance in addition to gentle product handling. Both challenges are met by the Blister machine BLU 200.

Variable packaging

The BLU 200 offers individual packaging solutions to meet all customer requirements. The combination of different feeding systems, the choice between sealed blisters or clamp packs, an optional extension of the fill section, and the integration of printing and inspection systems are among the options.

Flexibility extends to the cartoner

The Cartoner C 200 with its dual product feeder with two loaders ideally matches the wide format and output range of the blister packaging machine. If smaller products are packaged in cartons up to 85 mm in width, the pitch can be halved from 200 mm to 100 mm. The C 200 then practically doubles its maximum output to 200 cartons per minute.

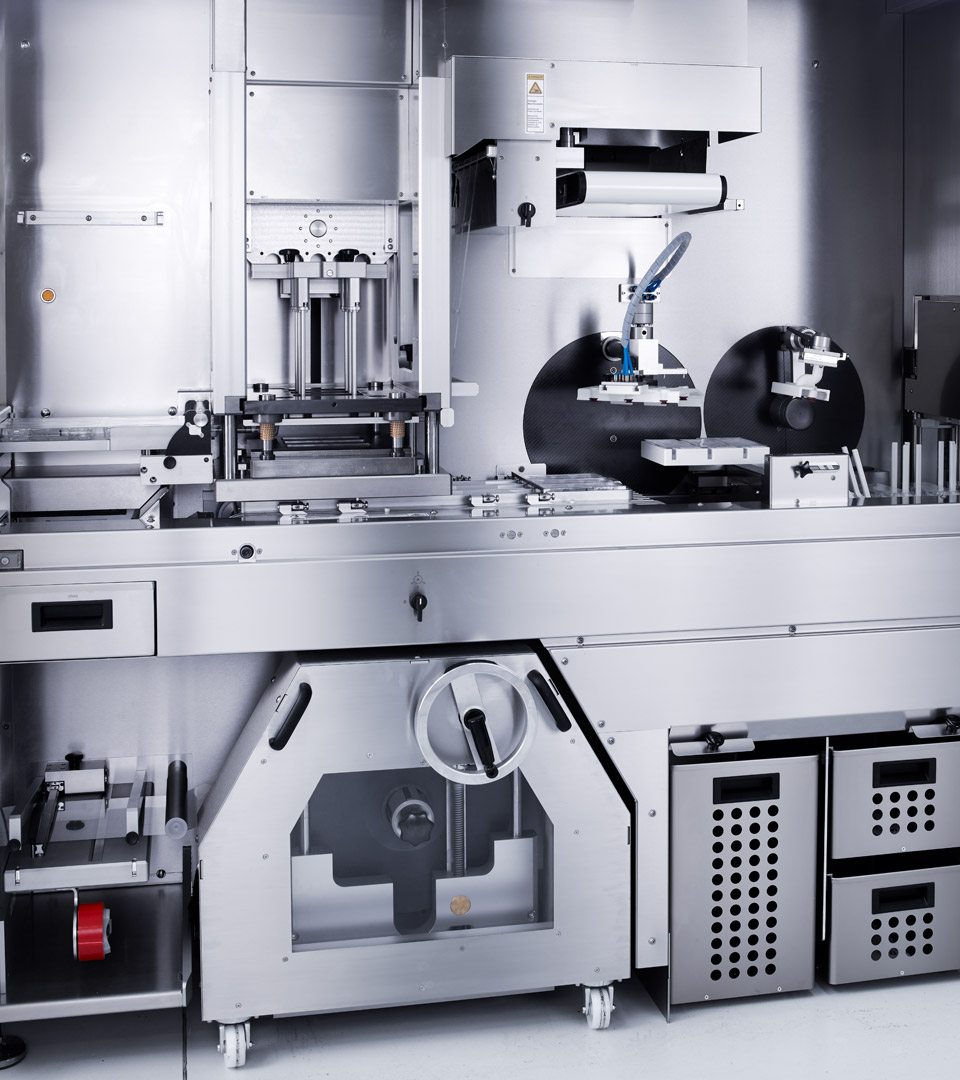

Gentle product handling

In addition to its flexibility, the BLU 200 impresses with the typical Uhlmann mixture of reliability and quality – crucial factors when packaging parenteral products. One example is the press-in process that eases the products into the pockets in two stages. This reduces the required pressure and thus minimizes the danger of damaging the products. As the cost of parenteral products is often high, gentle product handling features pay off. The machine design also allows the option of manual feeding

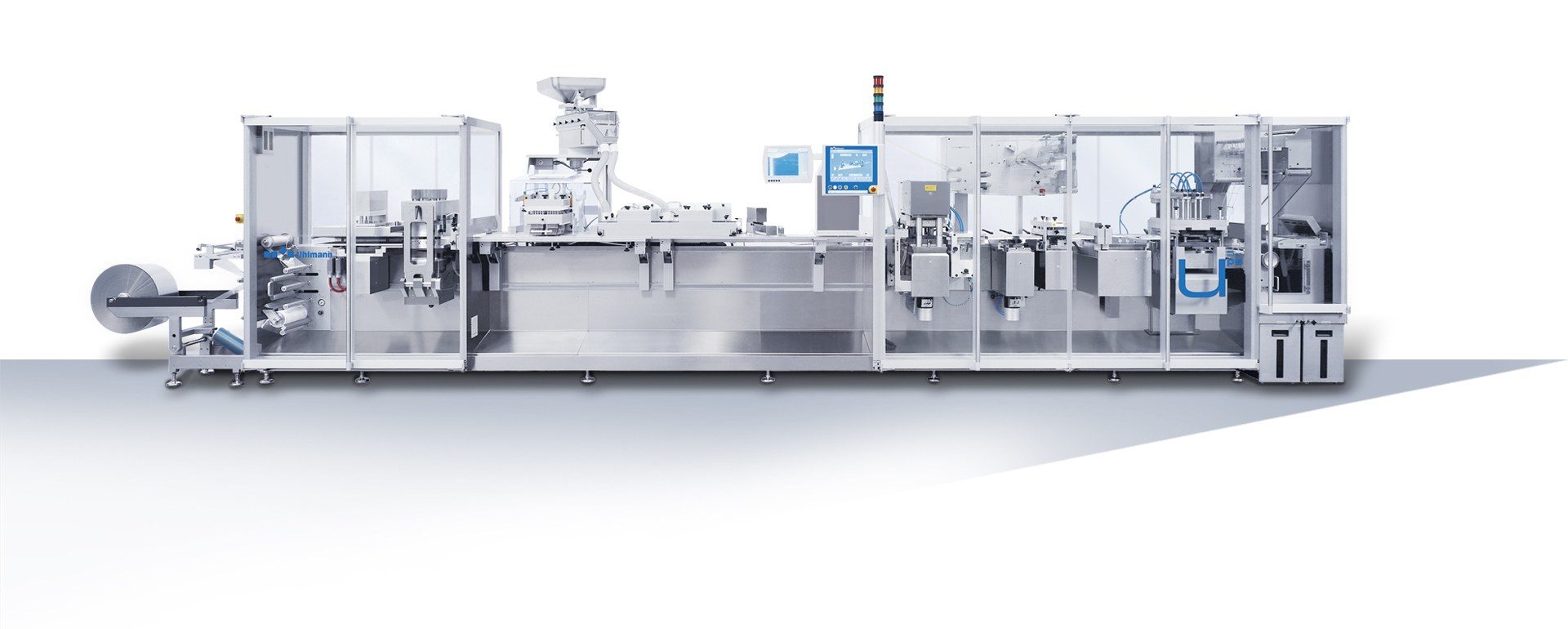

Optimum format utilization

As the BLU 400 operates with a product rotation function, full use can be made of the web width. In other words, products can be positioned both lengthwise and crosswise to the running direction of the web. The blister sizes ranges from 20 x 60 millimeters to 195 x 284 millimeters. In this context, it is not only the feeder that can position the products lengthways or crossways: the transfer of the filled blisters to the cartoner is correspondingly designed. A gripper places the blisters on a rotary table that turns 180° or 270° to allow insertion of the blisters in the carton.

Top efficiency and fast format changeovers

The low risk of glass breakage makes the BLU 200 very efficient. Added features include GMP-compliant design with smooth, high-quality surfaces, such as door panels made of glass, and excellent accessibility to all sections. These promote fast cleaning and short setup times. Only a few parts have to be exchanged for a format changeover – without the need for tools.

Future-oriented operating system

Characteristic of the SmartControl operating system of the BLU 200 is its straightforward and comprehensible interface. It provides intuitive user guidance through all production processes. After a short initiation period, employees are able to operate the machine confidently.

Newsroom

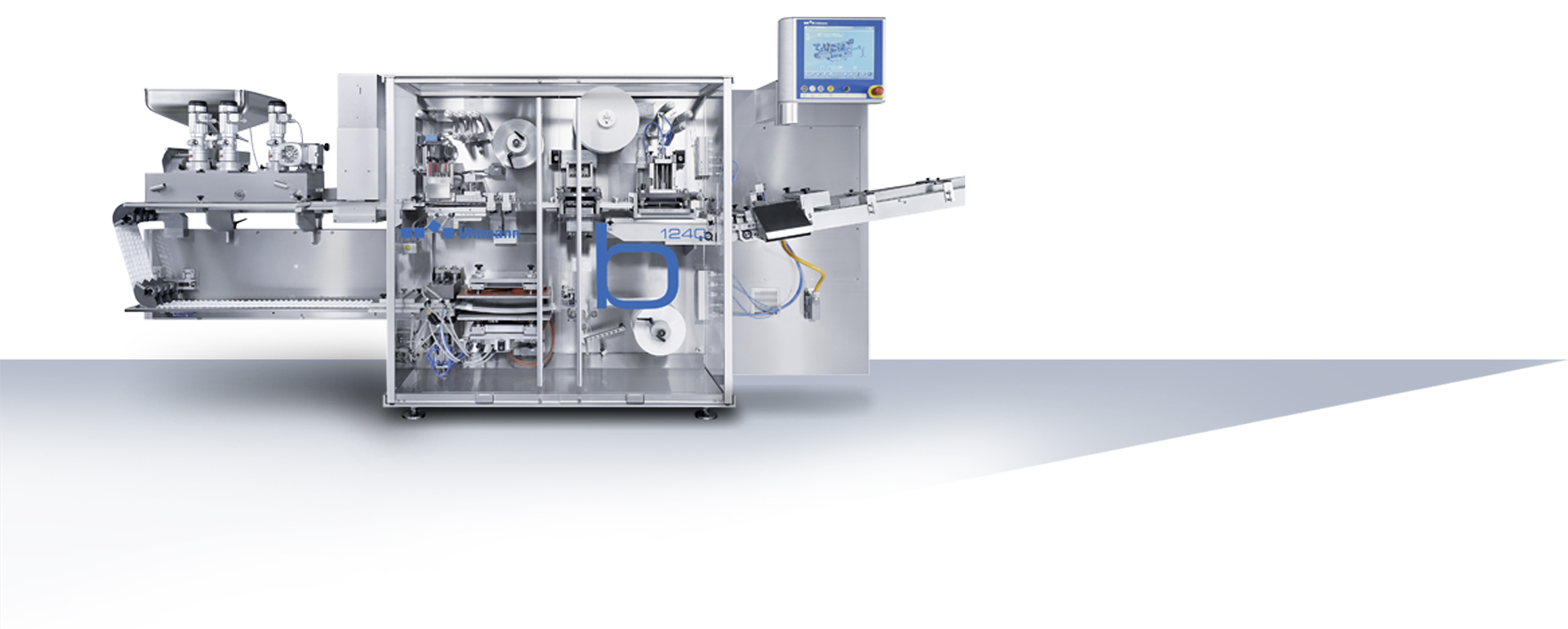

A comparison of our blister machines

| Max. Blisters/Min. | Max. format area [index x width] | Sealing principle | Scope of application | ||

|---|---|---|---|---|---|

| 200 or 300 | 200 x 145 mm | plate sealing | solid dose products | ||

| 200 | 173 x 206 mm | plate sealing | parenteral products | ||

| 400 | 195 x 284 mm | plate sealing | parenteral products | ||

| 400 | 272 x 284 mm | platen sealing | solid and parenteral products | ||

| 250 | 130 x 156.5 mm | platen sealing | solid and parenteral products | ||

| 300 | 200 x 145 mm | rotary sealing | solid dose products | ||

| 500 | 200 x 284 mm | platen or rotary sealing | solid dose products | ||

| 700 | 200 x 284 mm | platen or rotary sealing | solid dose products | ||

| 1,300 | 280 x 284 mm | platen or rotary sealing | solid dose products | ||